From border patrol vehicles to unmanned ground systems, the defense sector demands absolute reliability, both in the field and from its supply chain. At METEC, we’ve built our reputation by delivering exactly that: strong and smart metal components engineered for mission-critical performance.

Over the past decades, METEC has quietly become a trusted production partner for the defense industry. Established in 1993, originally serving the civilian automotive sector, our metalworking expertise and scalable manufacturing model have naturally positioned us to support high-requirement defense and security projects across Europe.

Where performance meets precision

Our capabilities cover a wide range of defense applications, including:

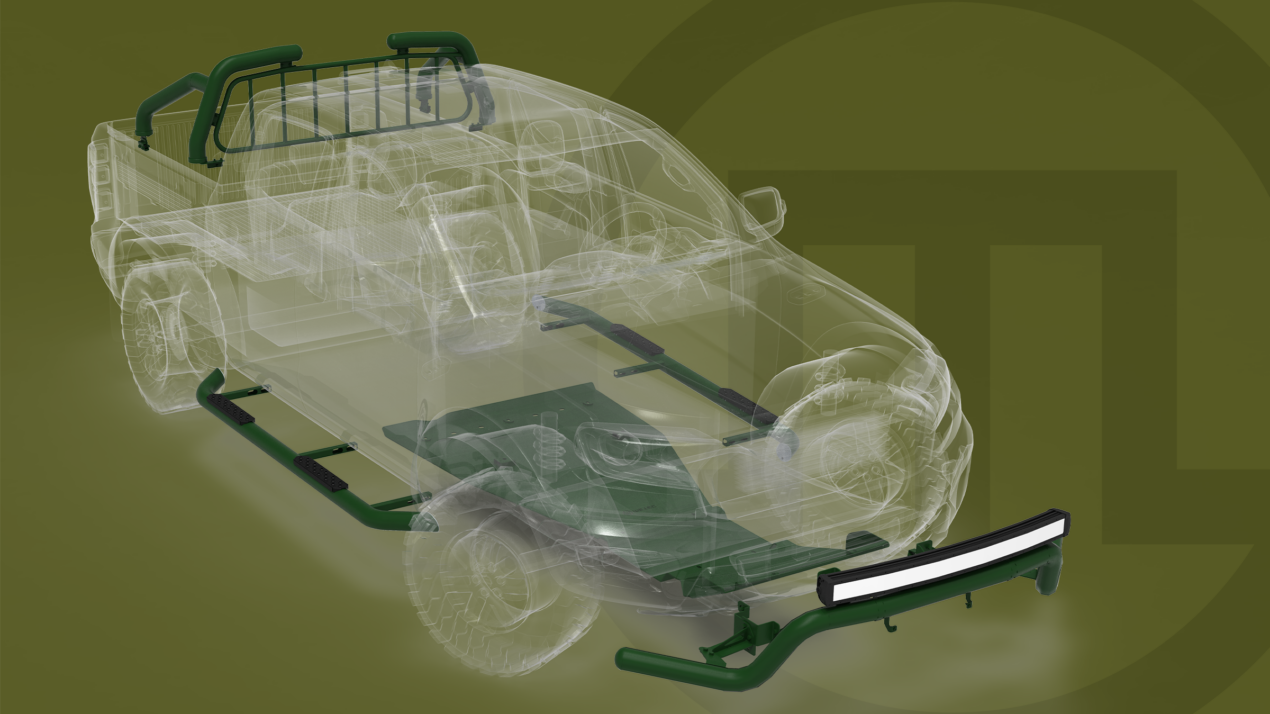

- Heavy-duty steel structures for unmanned ground vehicles (UGVs)

- Welded metal frames for armored vehicle seating systems

- Protection systems and auxiliary structures for tactical trucks

- Underbody protection systems used in military and border patrol fleets

Each solution is engineered and produced with defense-specific priorities in mind: mechanical strength, long-term durability, and manufacturing repeatability. Our experienced engineering team works closely with clients from the earliest design phase to ensure that each product is both technically optimized and production-ready, without driving up cost or lead times.

What sets METEC apart?

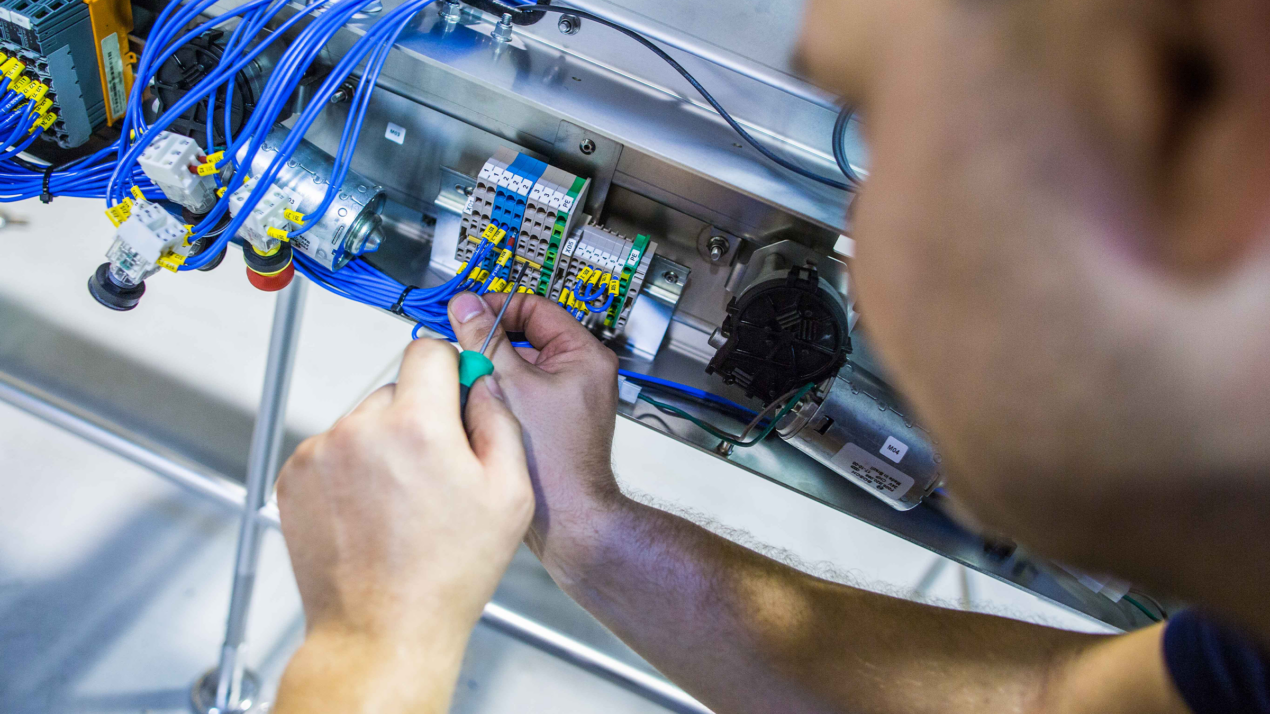

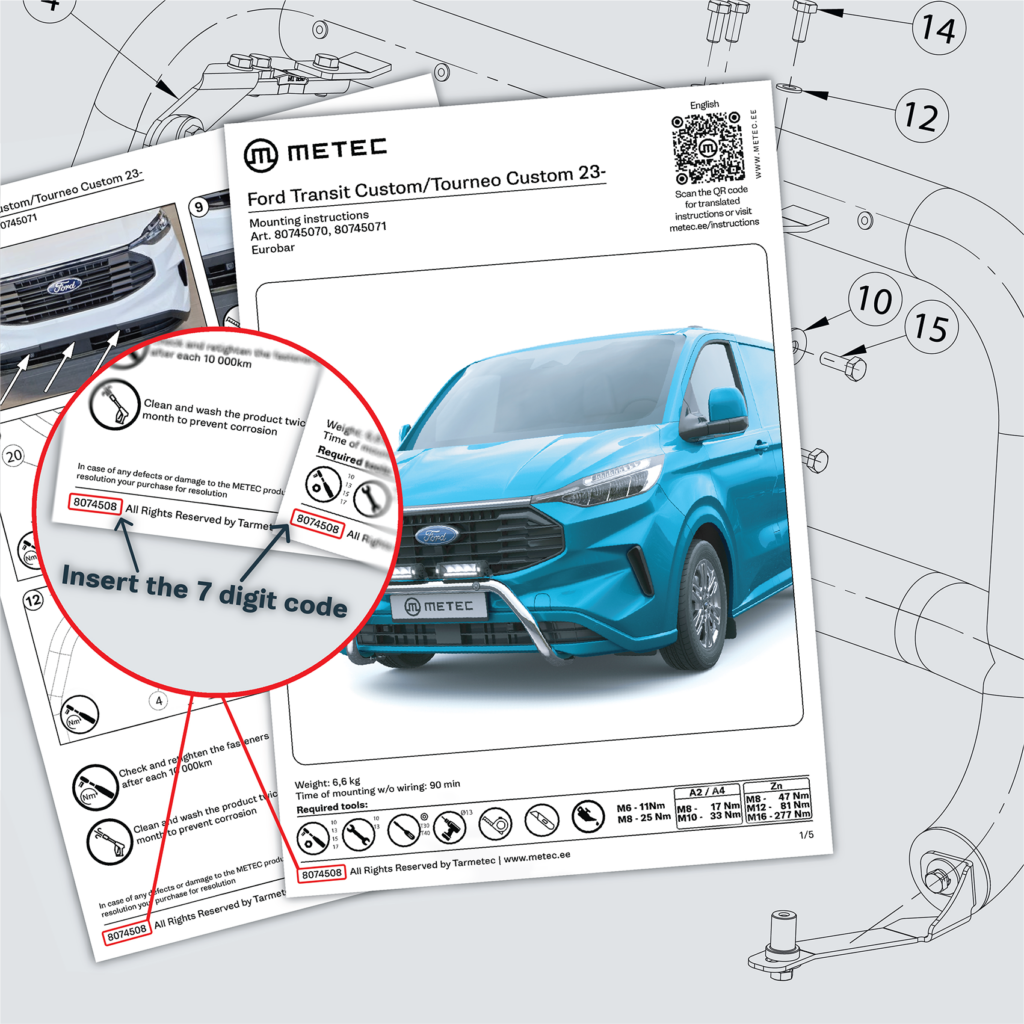

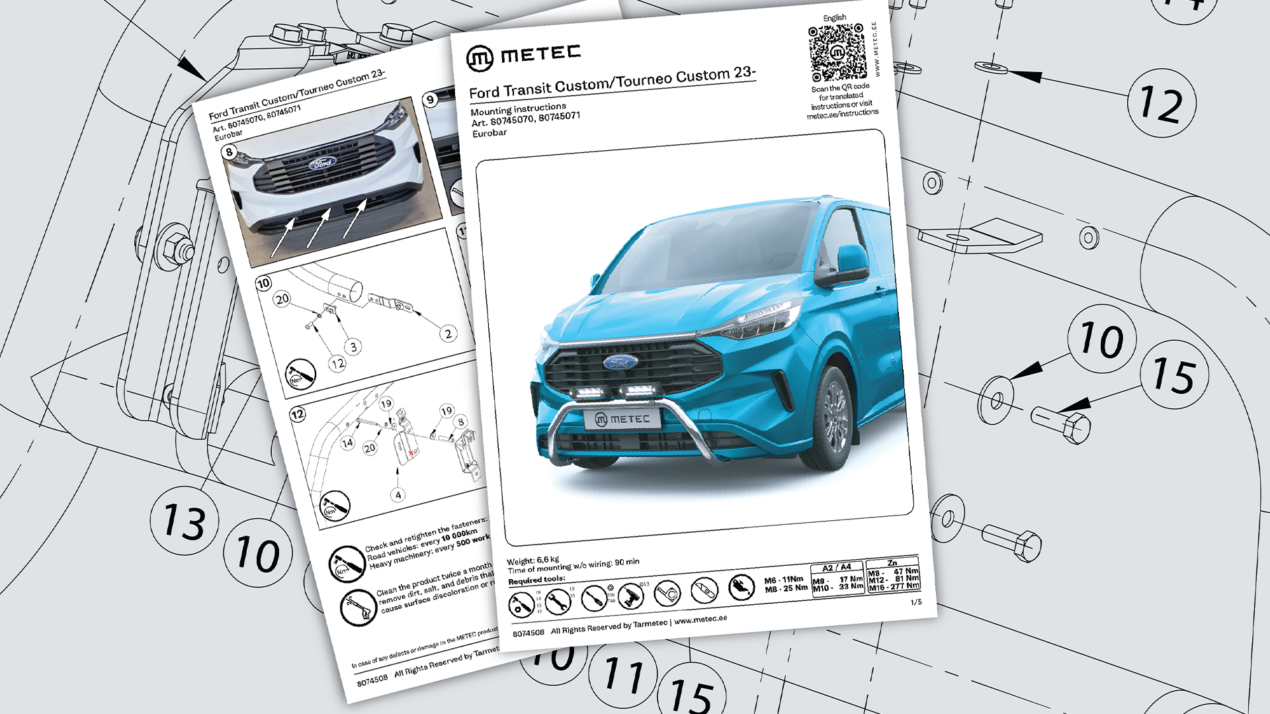

We share the same mindset as the defense and security industry – uncompromising quality, zero delays, and no tolerance for shortcuts. That mindset is backed by two major strengths: our in-house R&D, which enables rapid iteration and agile adaptation, and our manufacturing capability, which allows us to scale efficiently from small to large production volumes.

Whether you need a few dozen pre-series parts or thousands of units for a long-term contract, we have the structure and flexibility to deliver within weeks, not months.

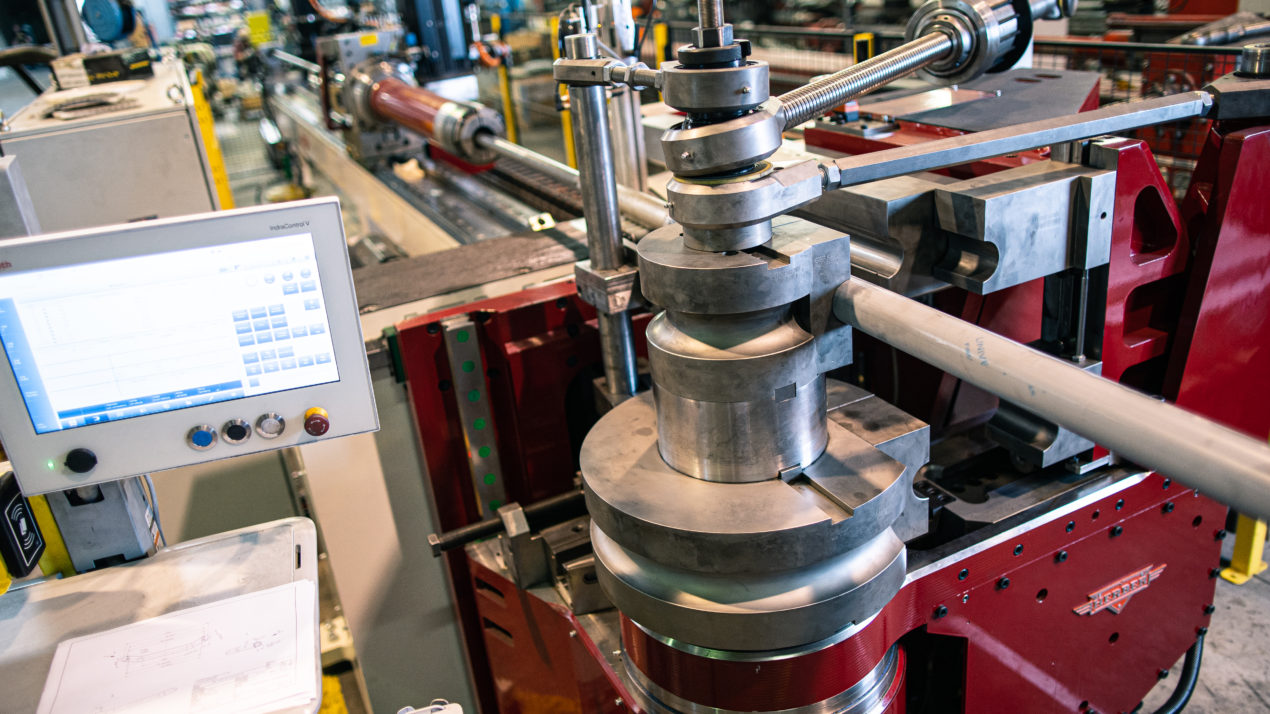

Modern facilities, proven results

Our production sites in Tartu are equipped with advanced CNC machining, robotic and manual welding lines, surface finishing, and ESD-safe assembly areas. We operate under strict quality protocols and are certified to meet critical standards, including ISO 3834-2 and EN 15085.

Over the years, our products have been integrated into various European defense fleets, including the Dutch and Danish armies’ Scania Gryphus trucks and over 200 vehicles in the Lithuanian Border Guard fleet. From lightweight skid plates to load-bearing substructures, we’ve consistently met field performance expectations under real-world military conditions.

Looking ahead

As defense needs evolve and vehicle platforms become more complex, METEC is committed to supporting innovation with reliable, precision-built metal solutions. We are exactly the right partner when it’s time to turn promising concepts into production-ready, field-proven components.

When duty calls, we deliver!

BACK

BACK